Its important to note that the specific design, size, and performance specifications of rack and pinion rotary actuators may vary depending on the manufacturer and the requirements of the application.

SPECIFICATIONS

●Working Pressure up to 210 bar

●Torque up to 40.000 Nm

●Angle of Rotation up to 720°

●Foot Mounting

●Front Mounting

●Maximum torque

●Short axial overall length

●Very short angle play

●Extremely study

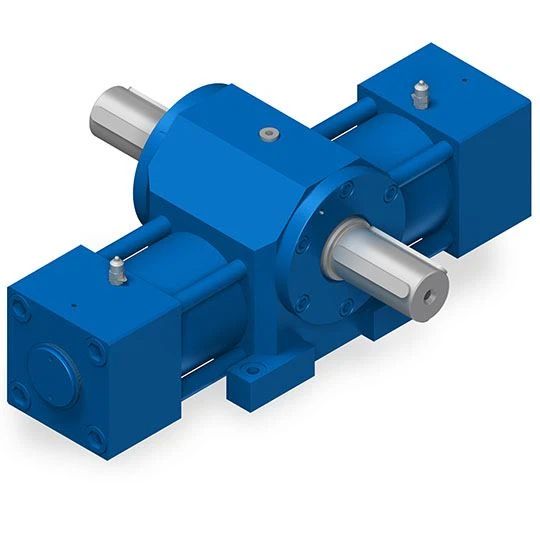

Rack And Pinion Rotary Actuator

Operation: The actuator consists of a cylinder with a circular piston inside and a rack attached to the piston. A pinion gear meshes with the rack. When pressurized fluid is applied to one side of the piston, it moves, pushing the rack along the pinion gear. This motion causes the shaft connected to the pinion gear to rotate, generating rotary motion.

Industrial Applications: Rack and pinion rotary actuators are used in various industrial applications that require rotary motion. Some common applications include upending, turning, roll-over, tilting, indexing, transferring, mixing, valve operation, tensioning, and clamping. They are utilized in a wide range of industries such as waterworks, sewage works, steelworks, chemical and pharmaceutical industries, shipbuilding, food industry, power plants (including geothermal, solar thermal, biogas, and conventional power plants), refineries, pipelines, tank farms, and more.

Versatility: Rack and pinion rotary actuators offer versatility in terms of the range of rotary motion they can provide. They can be designed to provide continuous rotation or limited-angle rotation as required by the application.

Power Transmission: These actuators are capable of transmitting high torque, making them suitable for applications that require strong rotary force.

Reliability: Rack and pinion rotary actuators are known for their reliability and durability, making them suitable for demanding industrial environments.

Inquire Form